Routine maintenance is the key to ensuring that explosion-proof electric cylinders maintain excellent explosion-proof performance and operating conditions for a long time. It is like conducting regular physical examinations on explosion-proof electric cylinders, which can detect and resolve potential problems in a timely manner and extend the service life of the equipment.

Inspecting the integrity of the explosion-proof electric cylinder housing is a crucial part of maintenance work.

The chemical production environment is complex, and the housing of explosion-proof electric cylinders may be affected by various factors such as physical impact and chemical corrosion. Regularly check the housing for cracks, deformation, wear and other damages. If any problem is found, repair or replace the housing in a timely manner to ensure its structural strength and sealing performance, preventing flammable and explosive substances from entering the interior of the electric cylinder.

The inspection of the sealing performance of explosion-proof electric cylinders should also not be neglected.

Effective sealing is the critical line of defense against the intrusion of flammable and explosive gases and dust into explosion-proof electric cylinders. Regularly check sealing components such as sealing rings and gaskets for aging, damage or loss of elasticity, and replace defective sealing parts promptly to ensure the sealing performance of explosion-proof electric cylinders remains in good condition at all times.

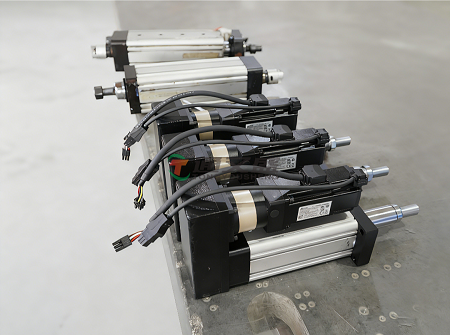

The inspection of the electrical connections of explosion-proof electric cylinders is equally important.

Loosening, oxidation and other issues at electrical connection points may lead to increased contact resistance and spark generation, thereby causing safety accidents. Regularly inspect electrical connection parts to ensure they are securely fastened without loosening. At the same time, check wires and cables for damage or aging, and replace them immediately if any problem is identified.

Regarding the maintenance cycle, it is generally recommended to conduct a visual inspection of explosion-proof electric cylinders once a week, including checking housing integrity and surface cleanliness; inspect the sealing performance and electrical connections once a month.

Conduct a comprehensive performance test of explosion-proof electric cylinders once a quarter, including tests on accuracy, stability, and resistance to impact and vibration.

If the explosion-proof electric cylinders are used in an extremely harsh environment such as high temperature, high humidity, or strong corrosion, the maintenance cycle should be appropriately shortened and the inspection frequency increased to ensure the equipment is always in optimal operating condition, providing a strong guarantee for the safe and stable operation of chemical production.