During operation, chemical equipment often generates intense impact and vibration due to mechanical operation, fluid impact and other factors.

For example, large compressors produce periodic vibration during operation. If such vibration is transmitted to explosion-proof electric cylinders, it may cause loosening of components, increased wear and even affect their normal operation.

Therefore, explosion-proof electric cylinders shall be designed with outstanding impact and vibration resistant structures.

Some explosion-proof electric cylinders are equipped with special shock-absorbing rubber pads and spring shock absorbers. Shock-absorbing rubber pads can effectively absorb and buffer impact energy, reducing the impact of shock on the internal structure of explosion-proof electric cylinders.

Spring shock absorbers isolate and attenuate vibration through the elastic deformation of springs, enabling explosion-proof electric cylinders to maintain a stable operating state even in vibrating environments.

At the same time, in the structural design of explosion-proof electric cylinders, the connection strength of key components is enhanced. High-strength bolts and nuts are adopted and anti-loosening treatment is carried out to ensure that no loosening occurs between components under impact and vibration conditions. This guarantees the normal operation of explosion-proof electric cylinders under complex working conditions and provides a reliable safeguard for the stable operation of chemical production.

The requirements for explosion-proof electric cylinders in chemical explosion-proof scenarios are multi-dimensional and extremely stringent, covering all aspects such as safety performance, material structure, performance reliability, as well as selection and maintenance.

In terms of safety performance, advanced explosion-proof design and strict explosion-proof certification are the cornerstones for the safe operation of explosion-proof electric cylinders in chemical environments. Designs such as flameproof enclosures and intrinsically safe circuits fundamentally eliminate explosion hazards.

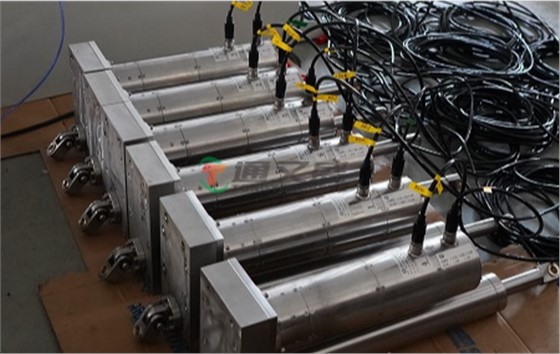

In terms of material structure, high-quality enclosure materials such as cast aluminum and stainless steel, as well as sealing and protection structures with high protection grades, enable explosion-proof electric cylinders to adapt to the harsh environments in chemical production and ensure the durability and sealing performance of the equipment.

In terms of performance reliability, high precision, stability, strong adaptability to working conditions, and impact and vibration resistance ensure that explosion-proof electric cylinders operate stably in complex chemical production processes and meet various production requirements.

In the link of selection and maintenance, correct selection and scientific daily maintenance are important guarantees for the long-term safe operation of explosion-proof electric cylinders. Enterprises must select suitable explosion-proof electric cylinders according to actual working conditions and conduct regular inspection and maintenance work.

When you need explosion-proof electric cylinders adapted to harsh working environments (such as high-temperature and dusty scenarios), or want to learn about key indicators such as the protection grade and service life of explosion-proof electric cylinders, please contact us. We will recommend special models that meet environmental requirements and provide application data under real working conditions.