The electronics industry is one that imposes extremely high requirements on precision and stability, particularly in the precision assembly process of electronic products. As electronic products continue to develop toward miniaturization, thinner and lighter designs, more stringent challenges are posed to the precision and stability of assembly equipment.

In traditional electronic product assembly lines, pneumatic cylinders were once one of the commonly used driving devices.

However, due to the fact that the control precision of pneumatic cylinders is difficult to meet the requirements of the electronics industry for the assembly of tiny components, problems such as component misalignment and poor welding are likely to occur during the assembly process, which affects product quality and production efficiency.

For instance, in the SMT (Surface Mount Technology) production of mobile phone motherboards, it is necessary to accurately mount tiny electronic components on circuit boards. The size of these components is usually only a few millimeters or even smaller, and the requirement for mounting precision reaches the micron level. When using a placement machine driven by a pneumatic cylinder, it is difficult to ensure that the position of each component is accurately placed. Issues such as component offset and cold soldering are prone to occur, resulting in a low product qualification rate.

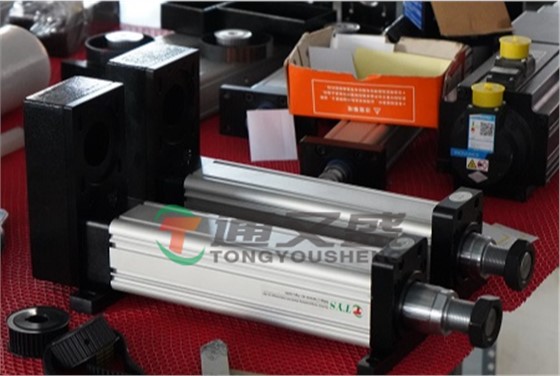

In contrast, high-speed electric cylinders, with their high precision and stability, have become key equipment for precision assembly in the electronics industry.

Taking an electronic manufacturing enterprise as an example, after introducing precision assembly equipment driven by high-speed electric cylinders, the production situation has been greatly improved. These devices adopt advanced high-speed electric cylinder technology and are equipped with high-precision visual recognition systems, enabling accurate grasping and mounting of electronic components.

During the mounting process, high-speed electric cylinders can precisely control the movement trajectory and position of the robotic arm based on the information fed back by the visual system. This ensures that electronic components can be accurately mounted at the designated positions on the circuit board, with a mounting precision of ±0.01mm, which significantly improves the product yield rate.

The high stability of high-speed electric cylinders also ensures the reliability of the equipment during long-term operation, reduces downtime caused by equipment failures, and improves production efficiency.

After electronic manufacturing enterprises start using assembly equipment driven by high-speed electric cylinders, the product yield rate has been increased, production efficiency has been improved, production costs have been effectively reduced, and the enterprises' competitiveness in the market has been enhanced.

The wide application of high-speed electric cylinders in the electronics industry has promoted the development of electronic product manufacturing toward higher precision and higher efficiency, and provided strong support for the continuous innovation and upgrading of the electronics industry.