In modern automated and intelligent equipment, electric cylinders are increasingly replacing traditional hydraulic and pneumatic cylinders to become the new favorite for linear motion control, thanks to their advantages of high precision, strong controllability, compact structure and easy maintenance. However, in practical applications, the spatial structure, force direction and motion trajectory of equipment vary greatly. This requires electric cylinders to flexibly adapt to a variety of installation methods to exert optimal performance in limited spaces. Then, how exactly can electric cylinders achieve diversified installation adaptation?

Technical Considerations for Selecting Electric Cylinder Installation Methods

To ensure that an electric cylinder "fits" the equipment seamlessly, it is recommended to evaluate the following aspects during selection:

Load Direction and Coaxiality

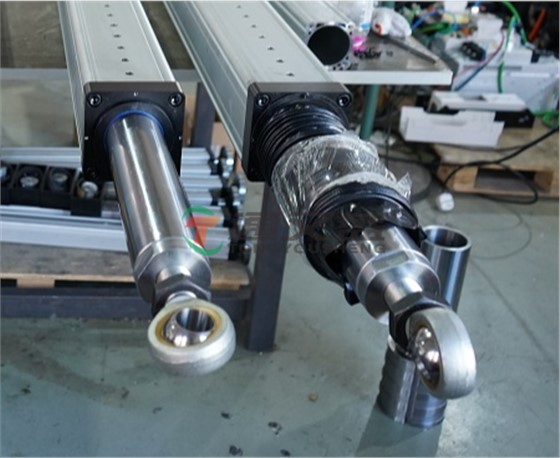

The push rod of the electric cylinder should be kept as coaxial as possible with the load to reduce lateral force. If lateral force cannot be completely avoided, articulated or clevis mounting is preferred to absorb deviations.

Space Constraints and Stroke Requirements

For long-stroke applications, horizontal installation of the electric cylinder may save more vertical space, while vertical installation facilitates pushing and pulling along the gravity direction. Flange mounting is suitable for scenarios with sufficient frontal space.

Dynamic Characteristics and Rigidity Requirements

Flange or base fixed mounting is suitable for high-frequency and high-rigidity positioning of electric cylinders. Articulated or clevis mounting can be used when follow-up motion or angular deviation compensation is required.

Ease of Maintenance and Replacement

Pin-hole and clevis mounting allow for quick disassembly and assembly, making them ideal for equipment that requires frequent maintenance or adopts a modular design.

Environmental Factors

For special environments such as high temperature, dust and humidity, the protective accessories matching the installation method (e.g., adding dust covers and isolation plates) should be combined to ensure the reliable operation of the electric cylinder.

If you are worried about the high installation difficulty of electric cylinders and the need for professional technicians, or want to learn about the installation process and precautions of electric cylinders, feel free to contact us. We will provide detailed installation videos and manuals for electric cylinders, and arrange on-site guidance by technical personnel when necessary.