In the field of automated assembly, efficiency and precision are the two core indicators for measuring the competitiveness of production lines.

The traditional "cylinder-driven" or "manual-assisted" modes can no longer meet the current assembly requirements for high speed, high precision and high consistency.

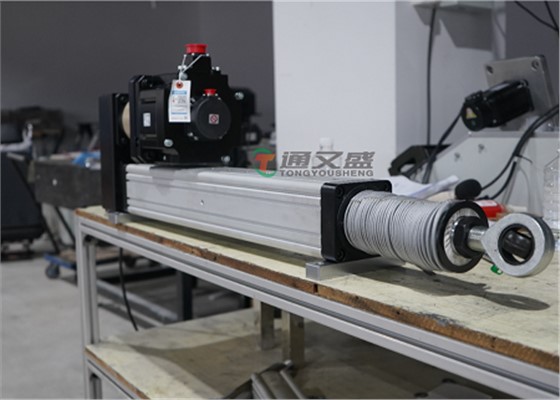

A growing number of equipment manufacturers and production line integrators have begun to adopt high-precision electric cylinders as the core actuators of assembly units, so as to achieve more accurate control, more stable performance and more flexible production rhythms.

Then, how exactly do high-precision electric cylinders help assembly lines achieve the "dual improvement of efficiency and precision"? What unique advantages do they possess?

Efficiency Optimization: Flexible Control Unlocks "Time Potential"

Through real-time adjustment of the servo system, high-precision electric cylinders can achieve millisecond-level start-stop and continuous variable-speed motion (with acceleration up to 5–10 m/s²), greatly reducing the transition time of a single action.

High-precision electric cylinders also support multi-axis linkage programming, enabling precise coordination of complex motion paths with ease. For example, in the entire process of "part picking, alignment, press-fitting and inspection", high-precision electric cylinders can dynamically adjust the motion rhythm based on sensor feedback, eliminating the fixed waiting time inherent in traditional solutions.

Intelligent Adaptation: Seamless Integration with Industrial Internet

As standard electrical actuators, high-precision electric cylinders inherently support communication with PLCs, industrial robots and vision systems (via protocols such as EtherCAT and PROFINET), and can upload real-time operational data including position, force and temperature.

When paired with an MES system, high-precision electric cylinders enable closed-loop management that covers "automatic issuance of process parameters, real-time monitoring of process data, and rapid response to anomaly alerts".

For instance, if a press-fitting force exceeding the set threshold is detected, the system can immediately stop operation and trace the operational records of the high-precision electric cylinder at the specific station, confining quality issues to the smallest possible scope.

Whether you need high-precision electric cylinders for upgrading automated production lines, or customized solutions for precision equipment R&D, we welcome you to contact us at any time. Our professional team will provide you with detailed product specifications, quotation proposals and technical support at the earliest opportunity.