In university scientific research, experimental simulation is a key link in exploring scientific principles and verifying theoretical hypotheses. Small-sized high-speed electric cylinders provide high-precision motion control and force control support for experimental simulation, significantly improving the automation level of experiments and the accuracy of data.

Take the experiment on material fatigue performance research as an example, which requires simulating the cyclic stress process of materials under different load conditions.

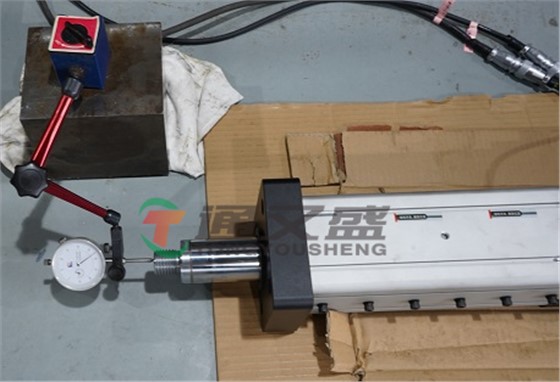

Researchers selected the TYSC series small-sized high-speed electric cylinders from Tongyusheng Small-Sized High-Speed Electric Cylinder Manufacturer. These electric cylinders have a repeat positioning accuracy of ±0.01 mm and a target speed of up to 100 mm per second, while also supporting variable speed control.

During the experiment, through programming settings, the small-sized high-speed electric cylinders can accurately output forces of different magnitudes, simulating the alternating loads that materials bear under actual working conditions.

Multiple electric cylinders can operate synchronously to ensure uniform deformation of the sample during the stress process, avoiding deviations in experimental data caused by uneven stress.

During the experiment, according to the preset program, the small-sized high-speed electric cylinders perform repeated tension-compression operations on the material sample at a specific frequency and displacement.

Real-time monitoring of the output force is conducted through pressure sensors. When there is a slight change in the stress on the sample, the small-sized high-speed electric cylinders can respond quickly, adjust the output force, and perform follow-up actions based on the deformation of the sample, always maintaining the set load level.

The application of small-sized high-speed electric cylinders makes the load on materials during the experiment closer to real conditions, and the obtained data more reliable, providing a solid data foundation for research such as material fatigue life prediction.

The entire experimental process has realized automation. Researchers do not need to manually adjust equipment parameters frequently, which greatly improves experimental efficiency, reduces errors caused by human operations, and promotes the smooth development of innovative research projects in the field of materials science.